Description af work

The aim of this work package is to assess the TailorCrete concept in the life cycle regarding cost, sustainability, safety and aesthetics. The focus is on differences, with the aim to identify added benefits and possible new issues compared to traditional approach.

Life cycle stages

Life cycle Cost

The aim is to perform the life cycle cost analysis of the selected representative structure and compare between traditional and TailorCrete processes. This evaluation has been preformed on the full scale demonstrator, built as a part of work package 7. By analyzing the entire life cycle of a concrete structure, only the design and partially the construction phase are different (TailorCrete vs. Traditional system) and have been analyzed.

Full Scale Demonstrator

Life Cycle Analysis

The sustainability of TailorCrete concept has been assessed by evaluating product’s energy use, and environmental carbon, water, and waste footprints. This life cycle screening has been carried out for the full scale demonstrator, built as a part of work package 7.

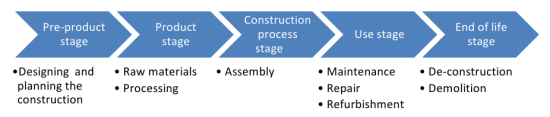

The evaluation covers the life cycle stages, of which only those related to reinforced concrete structures were selected: A1 – A5 (Production-Construction), B1-B5 - Use stage (use, maintenance, repair, replacement), C1-C4 - End-of-life stage.

The environmental data for the processes and materials are primarily given through models made in GaBi sustainability software. Specific data is used for the cement and fly ash.

Safety in the life cycle

The TailorCrete concept is relying on the application and development of advanced technologies: digital design tools, new automated formwork systems and reinforcement types, and processing technologies. It is important to show that this concept should not worsen already existing concerns, connected with traditional technology, or gives rise to new safety issues.

Aesthetic evaluation

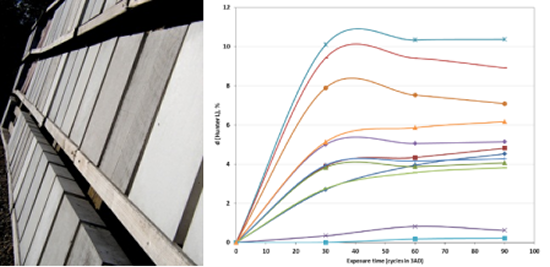

The degradation of aesthetic factors has been assessed using accelerated tests. Altogether 12 samples with different conventional or SCC recipes have been casted following the same procedure in different laboratories with similar hydration time. Three rounds of 30 cycles plus one last round of 40 cycles were performed with measurements to determine color stability and uniformity.

Samples for aesthetic evaluation, color stability measurements

Main achievements

- Assessments made on Full Scale Demonstrator

- It can be concluded, that the TC concept will be comparative with the nowadays traditional methods in terms of cost once it enters the common and broader use.

- The use of advanced materials and processing techniques leads to many advantages over the traditional approach, particularly in terms of superior aesthetic quality and durability.

- Some existing safety issues of traditional approach have been eliminated.

- TC may be the only option, regardless its cost, for construction of reinforced concrete buildings of complex shapes with high double-curvature or even of a free form, which is in line with today’s architectural trends.

WP leader: Czech Technical University