Description of work

Aim

For the dissemination and exploitation of the TailorCrete concept, it is extremely important that current standards and codes do not constitute obstacles or major limitations to the practical use of the concept. The aim of this WP is to clarify to the relevant technical WPs, where such obstacles may be encountered, along with providing input as to how to possibly overcome these.

Approach

The work in WP9 is divided into three deliverables.

Current standards and codes that apply to the various subjects of the project will be scrutinized and the possible barriers caused by these to the use of the TailorCrete concept will be identified (Deliverable 9.1). If such barriers or limitations are uncovered, this information will be given to the relevant WP. In close cooperation with the relevant WP, one of the following two models will be used for solving the obstacle:

- Suggestions on modifications of the TailorCrete concept to make it comply with the standard or code (deliverable 9.2), or

- Suggestions to future modifications of the standard or code in order to eliminate the barriers for the uses of the TailorCrete concept (deliverable 9.3).

Furthermore, it will be investigated if existing EU directives or regulations may serve as “drivers” or barriers for the use of the project results.

Each of the deliverables covers the three tasks: formwork (WP2), reinforcement (WP3), and SCC (WP6), as it is mainly the developments within these WPs that may result in possible conflicts with the current standards, codes and directives.

Deliverable 9.1

This first deliverable contains a survey of standards, codes, and national as well as international guidelines that may affect application of project results from WP2 (formwork), WP3 (reinforcement), WP6 (SCC), and WP7 (full scale). The latter is incorporated into considerations on the first three subjects.

Formwork

- Under the European Directive for Building Products a large number of product standards for precast products have been issued over the past couple of years.

- These product standards all refer to:

- EN 13369 Common rules for precast concrete products

- EN 1992 Eurocode 2: Design of concrete structures

- Furthermore, scaffolding is regulated by a number of standards

- Besides this, the support must also comply with the Eurocodes

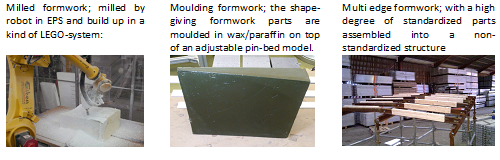

In TailorCrete WP2 – New formwork types, three systems are currently being investigated. These systems are:

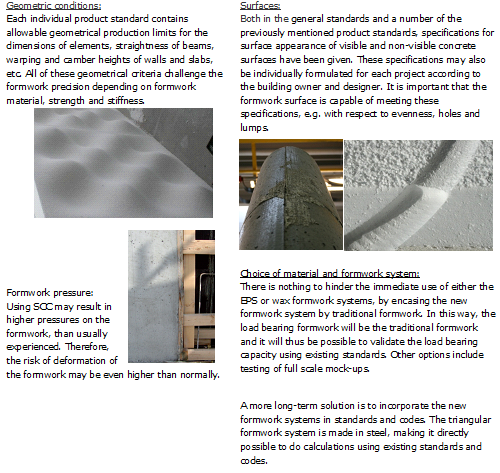

For formwork, there are especially four things to consider:

Reinforcement

In TailorCrete WP3 – Reinforcement types, focus is on traditional reinforcement bars, steel fibre reinforcement, and to a certain extend textile reinforcement. The extend of research on textile reinforcement will merely be on a conceptual scale since the technology is not very far along, leaving the WP9-focus on traditional reinforcement and steel fibre reinforcement. Below, a summary of status for these two areas is given:

- Traditional steel bars and pre-stressing steel reinforcement are covered in product standards (still under construction)

- Specifications and criteria for the use of reinforcing steel in structural concrete are given in the Eurocodes

- The execution on-site is governed by EN13670 Execution Standard

- No Eurocodes exist for calculation of fibre reinforced concrete. However, a number of guidelines have been published, among these are:

- Fib Model Code 2010

- RILEM TC 162-TDF

- German Part of Annex 14

- Spanish EHE-08

Based on especially the fibre reinforcement guidelines mentioned above, the following thing should be considered:

- Recommendations for design process with finite element analysis are lacking for structures with fibres and fibre/traditional combinations.

- Shells with fibre reinforced concrete are sparsely covered with regard to verification of safety and serviceability.

- Structural concrete members such as continuous beams of fibre reinforced concrete need to satisfy ductility requirements. However, there is no method proposed.

- The methods for calculating the deflection of fibre reinforced concrete structures need some clarifications.

- The material response of high and ultra high strength concrete is not covered in the recommendations for fibre and fibre/traditional reinforcement

Self-compacting concrete (SCC)

The relevant standards include:

- EN 13670 Execution of concrete structures

- EN 206-1 Concrete – Part 1: Specification, performance production and compliance

- EN 206-9 Additional Rules for Self-Compacting Concrete (SCC)

A number of guidelines exist. Of these, the following have been selected for evaluation in TailorCrete:

- The European Guidelines for Self-Compacting Concrete – Specification, Production and Use, by BIBM, CEMBUREAU, ERMCO, EFCA and EFNARC, 2005

- Danish Technological Institute, ‘Guidelines for mix design of SCC’ and ‘Guidelines for execution of SCC’, 2007.

- Norwegian Concrete Association, ’Spesifikasjon og produktionsveiledning for selvkomprimerende betong’, Publication No. 29, 2007 (in Norwegian).

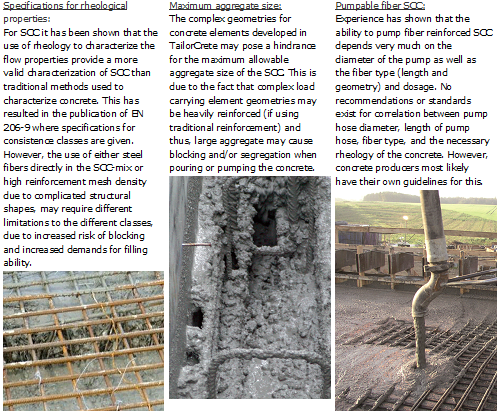

Based on the above, the following three things should be considered:

Conclusions

There are several possible ways to introduce the developed formwork systems to market. Some of them must be on a case-by-case basis, and some may be an overall approval. In general, however, there doesn’t seem to be an actual hindrance to introducing the systems. The cost of using the system will be the main barrier, but this will differ from each case, and cannot be further described in the present report.

Possible limitations on rheological properties imposed by the TailorCrete system must be based on the developed mix designs including fibers, as well as input regarding traditional reinforcement mesh density, and resulting necessary SCC rheological properties. When this input is available, the resulting barriers or drivers derived from this will be evaluated as a part of DL9.2.

To be able to use fibre reinforced concrete as load bearing in combination with traditional reinforcement, there is a need for further development of the available guidelines and codes. In addition, to meet the need for industrial thinking of the TailorCrete concept, the design process needs to involve finite element methods to become rational.

Based on the above, the use of fibres as fully or partly load bearing reinforcement, poses by far the largest hindrance to the TailorCrete concept.

WP leader: Danish Technological Institute